产品描述

作为一家集研发、生产、销售为一体的矿冶设备及配件制造厂家,我们拥有先进的UG产品设计、数控加工中心、密炼机、开炼机、φ3.5m*13m硫化罐等一系列大型生产设备,拥有设备齐全的实验室。自2015年开始研发钢橡复合管产品,目的是为选矿、热电、化工等企业降低生产成本并提供更优质的产品服务,我公司从选材、设计方面分别对市面类似产品进行大幅度优化改进,2017年伊始,我公司开始在国内外大力推广此产品。

As a manufacturer of mining and metallurgical equipment and spare parts integrating R&D, production and sales, we are equipped with a series of large-scale production facilities such as advanced UG product design, CNC machining centers, internal mixers, open mills, and φ3.5m*13m vulcanizing tanks, as well as a fully equipped laboratory. Since 2015, our company has been engaged in the research and development of steel-rubber composite pipe products, aiming to reduce production costs and provide better product services for enterprises in the mineral processing, thermal power, chemical and other industries. We have made significant optimizations and improvements to similar products on the market in terms of material selection and design. At the beginning of 2017, our company started to vigorously promote this product both at home and abroad.

以目前我公司设备及人员配置情况,每年可生产DN100-DN400的钢橡复合管达50公里,生产DN500-DN800的钢橡复合管可达30公里。

Based on the current equipment and personnel configuration of our company, we can produce 50 kilometers of steel-rubber composite pipes with diameters ranging from DN100 to DN400 and 30 kilometers of steel-rubber composite pipes with diameters ranging from DN500 to DN800 annually.

作为大型矿山及国内外矿山设备配套供应商,质量是保证工程顺利实施的关键,我公司自成立以来一直将质量控制视为工作的重心之一,严格执行ISO9001质量管理体系,对原材料、半成品、成品进行严格考核和检验,制定ITP检验试验计划,通过严格的产品质量控制和管理,不断提高公司的品牌影响力。公司通过多年的不断完善形成了完整的质量管理和控制体系,对产品的原材料采购、加工过程、出库、质量统计、性能检验以及质量系统的各个方面进行严格监控和把关。公司建立了市场部、生产部、研发中心、销售部、售后部、质控部多部门共同控制产品质量的质量控制架构,公司设立专门的质控部对公司整体的内部控制及质量体系建设把关,生产检验由检验中心来具体执行,在整个生产的实施过程中由销售部和售后部共同把关,保证客户对产品质量的及时反馈。

As a large-scale mining company and a supplier of domestic and foreign mining equipment, quality is the key to ensuring the smooth implementation of projects. Since its establishment, our company has always regarded quality control as one of the focuses of our work. We strictly implement the ISO9001 quality management system, conduct strict assessment and inspection of raw materials, semi-finished products and finished products, and formulate ITP inspection and test plans. Through strict product quality control and management, the company continuously enhances its brand influence. Through years of continuous improvement, the company has established a complete quality management and control system, strictly monitoring and controlling all aspects of the product, including raw material procurement, processing, delivery, quality statistics, performance inspection, and the quality system. The company has established a quality control framework in which multiple departments, including the Marketing Department, production department, R&D center, sales department, after-sales department and quality control department, jointly control product quality. The company has set up a dedicated quality control department to oversee the overall internal control and quality system construction of the company. The production inspection is specifically carried out by the inspection center. Throughout the implementation process of production, the sales department and after-sales department jointly supervise. Ensure timely feedback to customers on product quality.

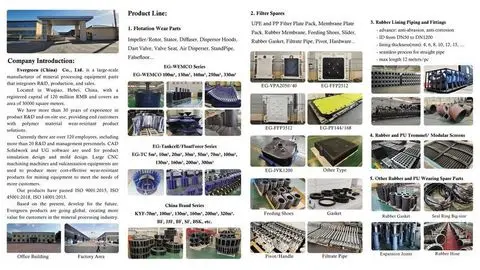

浮选机备件系列 Flotation machine spare parts series

浮选机备件系列在2000年由艾格瑞(中国)有限公司董事长王乃旺先生组建团队进行研发生产,起初主要生产北京矿冶研究院设计的浮选机定子转子,包括SF、KYF、XCF、JJF等各种型号定子转子,最大尺寸能做到160m³和320m³的KYF型浮选机定子转子,主要服务于乌山矿,到目前一直与乌山矿合作。2009年开始,团队和艾法史密斯合作,生产WEMCO和DORR浮选机定子转子,产品服务于铁矿、钾盐、钼矿选矿厂等,当时最大尺寸做到WEMCO和DORR的160m³浮选机定子转子,到目前一直与铁矿选矿厂合作。截至2013年,已经在国内的浮选机定子转子行业基本做到了型号最全、产品尺寸最大的生产。2015年,艾格瑞(中国)有限公司成立,浮选机定子转子业务快速发展。2016年开始研发WEMCO-330m³浮选机定子、转子、倒锥、竖筒、导流筒、锥阀等配套件,此型号为国内最大的浮选机。于2018年开始在国内客户铜矿厂开始试用,2019年开始量产此型号定子转子,截至2021年将客户铜矿厂的16台WEMCO-330m³定子转子进行全部更换。2020年开始生产TC型的定子转子,型号为TC-20、TC-50、TC-100、TC-200、TC-300等。截止目前,有关浮选机定子转子的生产从型号和产量方面还在不断扩大。

The flotation machine spare parts series was developed and produced by a team led by Mr. Wang Naiwang, the chairman of Evergreen (China) Co., Ltd. in 2000. Initially, it mainly produced flotation machine stators and rotors designed by Beijing Research Institute of Mining & Metallurgy, including various models such as SF, KYF, XCF, and JJF stators and rotors. The KYF type flotation machine stator and rotor with the maximum dimensions of 160m³ and 320m³ mainly serve Wushan Mine and have been cooperating with Wushan Mine up to now. Since 2009, the team has been collaborating with FLSmidth to produce the stator and rotor of WEMCO and DORR flotation machines. The products are used in iron ore, potash, molybdenum ore processing plants, etc. At that time, the largest size was the 160m³ stator and rotor of WEMCO and DORR flotation machines. Up to now, the team has been cooperating with iron ore processing plants. By 2013, it had basically achieved the production of the most complete models and the largest product sizes in the domestic flotation machine stator and rotor industry. In 2015, Evergreen (China) Co., Ltd. was established, and the business of stator and rotor for flotation machines developed rapidly. In 2016, the development of WEMCO-330m³ flotation components such as the stator, rotor, inverted cone, split tube collar, draft tube and dart valve began. This model is the largest flotation machine in China. The trial use of this model of stator and rotor began in the domestic customer's copper mine plant in 2018. Mass production of this model started in 2019. By 2021, all 16 sets of WEMCO-330m³ stator and rotors in the customer's copper mine plant had been replaced. The production of TC-type stators and rotors began in 2020, with models such as TC-20, TC-50, TC-100, TC-200, and TC-300. Up to now, the production of stators and rotors for flotation machines is still expanding in terms of models and output.

压滤机滤板、橡胶隔膜 Filter plates and rubber diaphragms of the filter press

艾格瑞(中国)有限公司作为一家集研发、生产、销售为一体的矿冶设备及配件制造厂家,拥有先进的UG产品设计、数控加工中心、4000mm*4000mm*6000T平板硫化机等一系列检测检验设备,自2016年开始研发有关美卓VPA20型滤板、隔膜板及橡胶隔膜产品,目的就是将此类产品国产化,为选矿企业降低生产成本并提供更优质的产品服务。我公司从选材、设计方面分别对原厂滤板系列产品进行优化改进,经我公司高级技术工程师悉心研究设计,于2017年在太钢集团尖山过滤作业区上机使用,截至目前已运行近5年,运行良好,2018年伊始,我公司开始在国内外大力推广此产品,目前已与太钢集团、鞍钢集团、招远黄金、中信泰富澳矿等多家矿企建立长期合作关系。截止2022年底我公司已成功开发美卓奥图泰VPA15系列、VPA20系列、FFP2512、FFP3512压滤机滤板及橡胶隔膜。

Evergreen (China) Co., LTD. as a manufacturer of mining and metallurgical equipment and spare parts integrating R&D, production and sales, is equipped with advanced UG product design, CNC machining centers, 4000mm*4000mm*6000T flat vulcanizing machines and a series of other testing and inspection equipment. Since 2016, we have been engaged in the research and development of Metso VPA20 filter plates, membrane plates and rubber diaphragms, with the aim of localizing such products to reduce production costs for mineral processing enterprises and provide them with better product services. Our company has optimized and improved the original factory filter plate series products in terms of material selection and design. After careful research and design by our senior technical engineers, they were put into use in the Jianshan Filtration operation area of Taiyuan Iron and Steel Group in 2017. Up to now, they have been running for nearly five years and have performed well. At the beginning of 2018, our company began to vigorously promote this product both at home and abroad. At present, we have established long-term cooperative relationships with many mining enterprises such as Taiyuan Iron & Steel Group, Ansteel Group, Zhaoyuan Gold, and CITIC Pacific Australia Mine. By the end of 2022, our company had successfully developed filter plates and rubber diaphragms for Metso Outotec VPA15 series, VPA20 series, FFP2512, and FFP3512.

- 浮选机定子转子

- 压滤机滤板

- 压滤机配件

- 浮选机配件

产能:

未通知

运输时间表:

未通知

Incoterms:

未通知包装明细:

未通知

更多关于

Evergreen (China) Co., Ltd.

100-200

员工

1

销售额(美元)

70%

% 出口销售额

Year

成立年份

业务类型

- Industry / Manufacturer

关键词

- 浮选机转子

- 浮选机定子

- 压滤机滤板

- 压滤机隔膜

- 分料器

联系方式和位置

-

Lisa ********

-

+86 1********

-

Dezhou / Shandong | 中国